HEADSHOKEXPERT

gallery of interesting problems

Damaged ridge of DLR compression valve

CAUSED BY: Insufficient tightness of assembly nut

SYMPTOMS: Lockout doesn’t work, lever rotates around

REMEDY: Clean debris from valve, retighten the assembly nut with a drop of Loctite

HOW TO PREVENT: Don’t let anyone but the expert near your fork

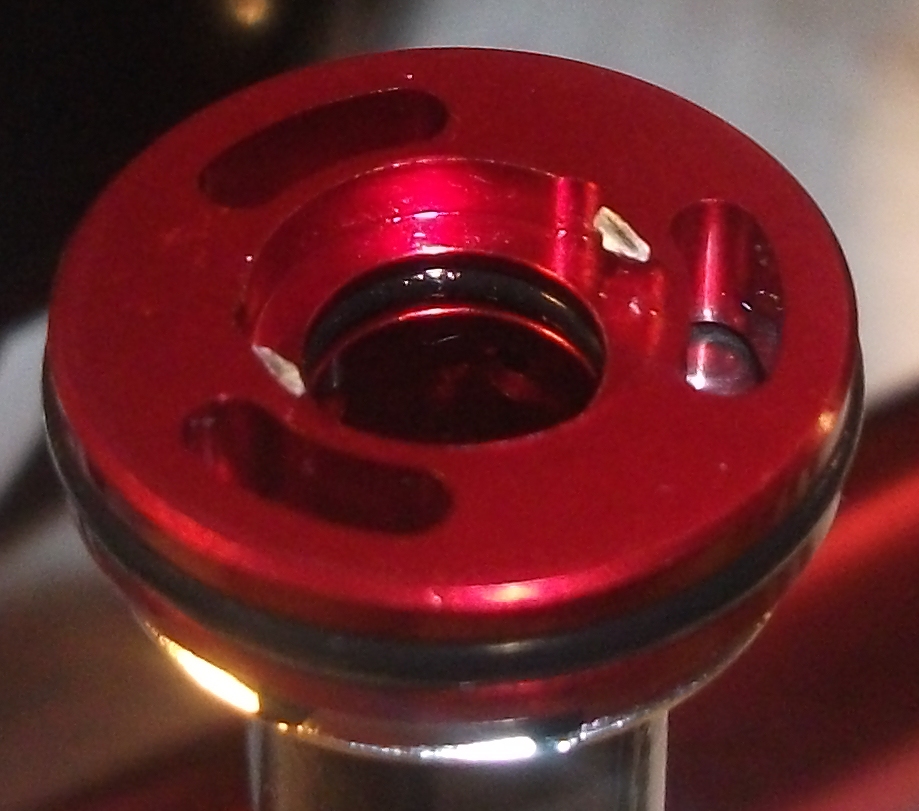

Broken o-ring seal on DLR lock lever

CAUSED BY: Inproper installation or maintenance. Water drained from the top down to the needle bearings.

SYMPTOMS: Harsh fork action

REMEDY: Corroded bearings and races should be replaced if beyond reparability.

HOW TO PREVENT: Regular maintenance intervals dicover the potential risk

Snapped air piston

CAUSED BY: Overtightening the air cilinder piston, threaded neck broken at piston connection point

SYMPTOMS: Impossible to keep any air in fork

REMEDY: Replace the plastic piston

HOW TO PREVENT: Don’t let anyone but the expert near your fork

Disintegrated elastomer

CAUSED BY: Age and/or improper maintenance (wrong grease!)

SYMPTOMS: No compression action at all

REMEDY: Replace the elastomer with coil spring or some combination

HOW TO PREVENT: Regular maintenance intervals

Worn out air inlet thread (Schrader)

CAUSED BY: Worn chuck on your air pump; too frequent air adding

SYMPTOMS: Can’t connect pump securely

REMEDY: Replace the lower fork cap that carries the air inlet or buy another honed air cylinder

HOW TO PREVENT: Put some fine oil on pump chuck and keep it clean and lubricated. Be gentle when mounting/dismounting the pump to your fork

Snapped shaft of lower damper rod (LockOut control shaft)

CAUSED BY: Excessive force during fork assembling

SYMPTOMS: Can’t control Lock Our function; Lower rod gets disconnected from lock out valve

REMEDY: Fix at HeadShokExpert

HOW TO PREVENT: Be gentle and sensible when working on the fork

Bent lock out shim and retainer plate

CAUSED BY: Too loose lock out shaft at the top nut (axial plane)

SYMPTOMS: Lock out lever is skipping; Can’t lock properly.

REMEDY: Fix at HeadShokExpert

HOW TO PREVENT: Don’t let anyone but the expert near your fork

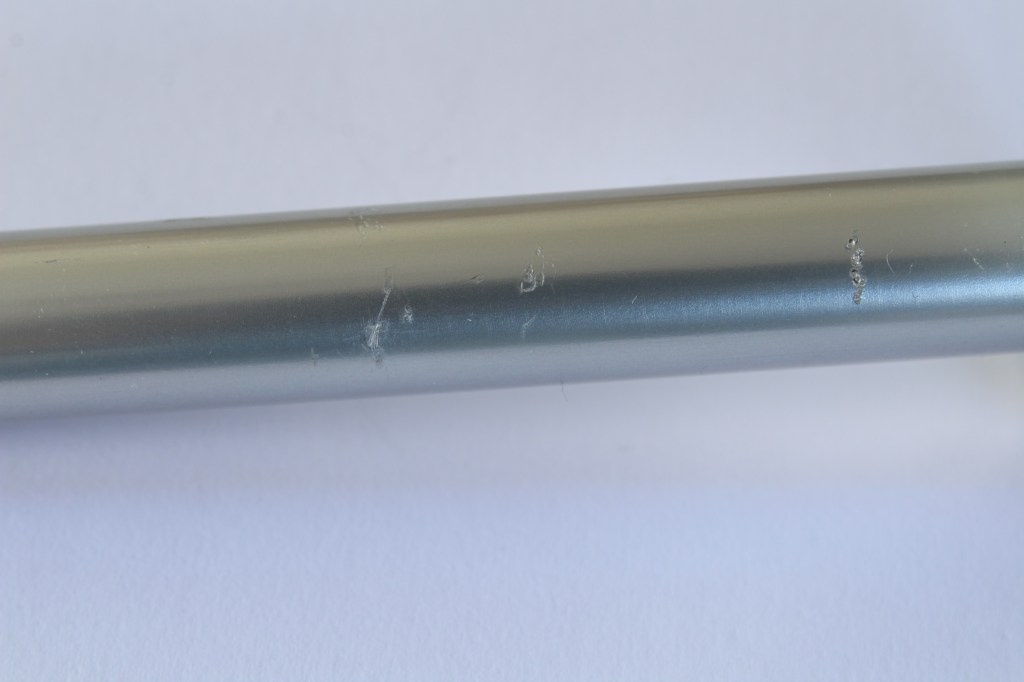

Scratched damper rod

CAUSED BY: Attempt to manipulate the damper assembly without original tools

SYMPTOMS: Lockout step due to oil leakage

REMEDY: Fill and polish the damage, replace rod seals, or replace the whole damper unit (200€!)

HOW TO PREVENT: Don’t let anyone but the expert near your fork

Corroded linear bearings needles

CAUSED BY: Whashing the bike with pressurized water (hose from a tap) over the fork top

SYMPTOMS: Harsh fork action

REMEDY: Replace needle bearing set and set of races

HOW TO PREVENT: Take care of the way you maintain your fork (bike)

Corroded needle bearing races on Lefty

CAUSED BY: Broken rubber boot let water inside

SYMPTOMS: Harsh fork action

REMEDY: Remove the rust mechanically, then polish the surface and turn inside out

HOW TO PREVENT: Regular maintenance intervals should discover the potential risk

Broken top-out spring

CAUSED BY: too high air pressure (according to spring stiffness type) or general material fatigue

SYMPTOMS: harsh top-out; air leakage due to scratched air cylinder

REMEDY: Replace the spring; polish out the damage if possible; upgrade to honed air cylinder

HOW TO PREVENT: Regular maintenance intervals. Keep air pressure within the limits of your spring type

Cracked inner wall of the rubber boot

CAUSED BY: Age and/or improper maintenance

SYMPTOMS: No symptoms

REMEDY: Replace the rubber boot a.s.a.p.

HOW TO PREVENT: This happens… but regular maintenance intervals can detect such deformations on time

Crashed needle bearing cage

CAUSED BY: Irregular bearing reset

SYMPTOMS: Harsh fork action

REMEDY: Replace the bearing cage

HOW TO PREVENT: Regular maintenance intervals